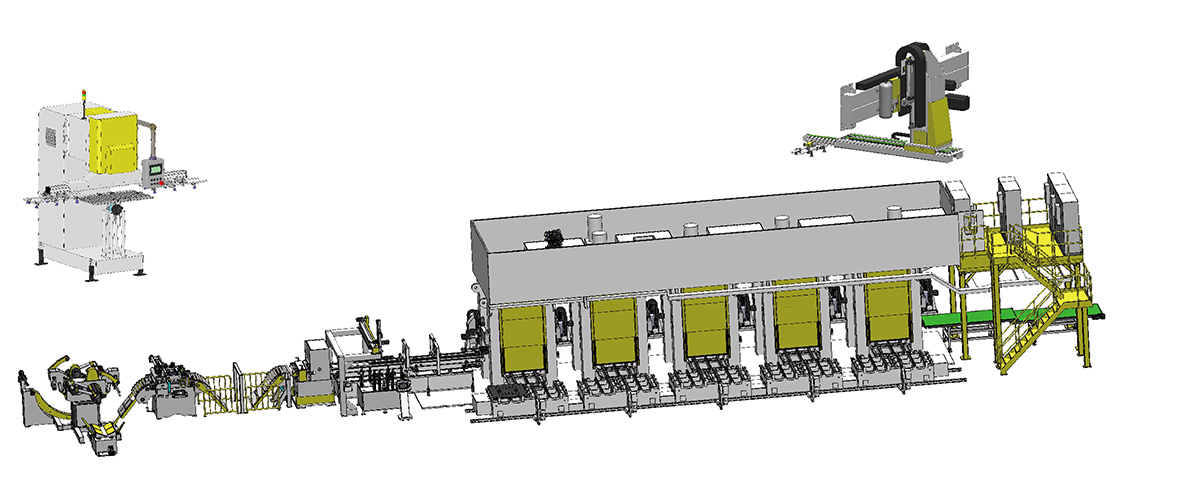

Multi Speeds Transfer System

- 2X, 3X, 4X speed transfer system, use for different situation

- lt can be X, Z axis or X, Y, Z axis speed transfer system

- Control system is motion control, Siemens system or Yaskawasystem can be selected. Advantage

Advantage

- No need all press center distance keep the

same, no need tool feeding height keep the

same, no need all press set in one line (if thereis Y axis design). So line set is flexible and easy.

- No middle station, so save space